Click image to enlarge

Solid Steel Rivets

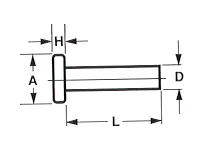

Steel fasteners are hardware devices that are used to mechanically join objects together. Solid steel rivets are a sturdy, effective, and permanent fastener option for a broad range of applications. They are relatively simple devices, comprised of a shaft and with a head (in one of a number of specific styles—see below) at one end. Like all steel fasteners, steel rivets provide a good combination of strength and durability, and are a more economical choice than those manufactured from most other metals or alloys.

Round Head

|

Flat Head

|

Countersunk Head

|

Truss Head

|

Pan Head

|

Universal Head

|

Your #1 Steel Rivets Suppliers

If you need steel solid rivets, you need Jay-Cee Sales & Rivet. We maintain a massive inventory of steel rivets, all in-stock and ready to ship. Our selection includes sizes, lengths, and head styles to fit any application. We carry:- Flat head solid steel rivets

- Pan head solid steel rivets

- Round head solid steel rivets

- Truss head solid steel rivets (a.k.a. wagon box rivets)

- Universal head solid steel rivets

- 90° countersunk head solid steel rivets

View our complete inventory to find the steel solid rivets you need, or use the filters at left to narrow your search results. With more than 700 steel rivet options available, we’re sure to have exactly what you need… and if we don’t have it, it probably doesn’t exist!

We are your #1 steel rivets suppliers. Order today, request a quote, or contact Jay-Cee Sales & Rivet to learn more.

How to Install Solid Steel Rivets

To install a steel rivet, the fastener is first inserted through matched drilled or pierced holes in two (or more) workpieces. Then, the headless end is struck with a hammer or a special riveting tool, which deforms the end of the shaft and creates (essentially) a second head. With both ends of the rivet now larger than the drilled/pierced holes, the rivet forms a reliable, permanent joint. Once installed, steel rivets can only be removed using tools which destroy the fastener.Standard Tolerances for Steel Solid Rivets

Diameter of Shank

| Nominal Diameter | Minus | Plus |

| 0.052-.094 | 0.001 | 0.003 |

| 0.095-0.156 | 0.001 | 0.004 |

| 0.157-0.219 | 0.002 | 0.005 |

| 0.220-0.375 | 0.003 | 0.006 |

Length of Shank

- Diameters of 3/4” up to 4” long, inclusive

- ±1/64” diameters to 3/4” lengths over 4”

- ±1/32” diameters over 3/4” to 4” long ±1/32”

- Diameters over 3/4” in lengths over 4” ±1/16”

Diameter of Head

As the heads of our solid steel rivets have not been machined or trimmed, the circumference may be irregular, and edges may be rounded or flat.The diameter of the rivet head shall be within -8° and +4° of the nominal head diameter.

Height of Head

+8°/-4° of the nominal or basic head height, but in no case less than ±0.005”.Out-of-Roundness of Head & Eccentricity of Head in Relation to Shank (In Inches)

| Nominal head diameter | Total dial indicator reading resulting from eccentricity and out-of-roundness not to exceed |

| Up to 1/4” | 0.015 |

| Over 1/4” to 3/8” | 0.020 |