Click image to enlarge

Solid Monel Rivets

Solid Monel rivets are an excellent fastener choice for demanding applications. “Monel” refers to a group of nickel alloys that provide enhanced capabilities to withstand conditions that other materials cannot. Monel rivets are commonly found in aerospace, marine, and oil and gas production/refinery applications, as well as in high end musical instruments, among other uses.

The material’s unique alloy composition gives solid Monel rivets a number of advantages, including:

The material’s unique alloy composition gives solid Monel rivets a number of advantages, including:

- High strength—Monel is stronger than pure nickel and many other pure metals

- Excellent resistance to corrosion

- Excellent resistance to seawater/marine conditions

- High acid resistance

- High melting point

- Exceptional toughness

- Maintains physical properties at extreme temperatures

Round Head

| Flat Head

|

Countersunk Head

| Truss Head

|

Pan Head

| Universal Head

|

Your #1 Monel Fasteners Suppliers

If you’re looking for Monel fasteners, look no further than Jay-Cee Sales & Rivet. We offer a large selection of Monel solid rivets, with sizes, lengths, and head styles to meet your requirements. Our inventory includes:- Round head solid Monel rivets

- Flat head solid Monel rivets

- 90° countersunk head solid Monel rivets

- 100° countersunk head solid Monel rivets

- Truss head solid Monel rivets (a.k.a. wagon box rivets)

- Universal head solid Monel rivets

View our full inventory below to find the right Monel rivets for your application, or use the filters at left to refine your search. With our comprehensive in-stock inventory, it’s easy to find exactly what you need.

We are your #1 Monel fasteners suppliers. Order today, request a quote, or contact Jay-Cee Sales & Rivet for more info.

Why Use Monel Rivets?

While Monel is one of the more expensive metal alloys available, it is not without good reason. The material’s chemical composition gives it mechanical properties and performance capabilities that most other metals can’t match. For example:- In aerospace applications, Monel rivets can withstand intense heat and pressure in combustion chambers that stainless steel cannot. This is thanks to Monel’s extremely high tensile strength (as much as 125,000 psi) and excellent corrosion resistance.

- In marine applications, Monel rivets provide far greater shear strength than aluminum, as well as higher corrosion resistance to withstand constant water/saltwater exposure and submersion. Monel does weigh more than aluminum, but not enough to offset these benefits.

- In structural/engineering applications, the higher tensile strength of Monel fasteners allows users to achieve the same results with far fewer rivets over aluminum or stainless steel, thereby reducing overall weight and assembly time.

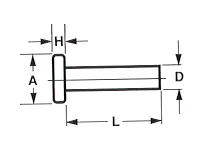

Standard Tolerances for Monel Solid Rivets

Diameter of Shank

| Nominal Diameter | Minus | Plus |

| 0.052-.094 | 0.001 | 0.003 |

| 0.095-0.156 | 0.001 | 0.004 |

| 0.157-0.219 | 0.002 | 0.005 |

| 0.220-0.375 | 0.003 | 0.006 |

| 0.376-0.625 | 0.004 | 0.008 |

| 0.626-0.875 | 0.006 | 0.012 |

| 0.876-1.000 | 0.007 | 0.015 |

Length of Shank

- Diameters of 3/4” up to 4” long, inclusive

- ±1/64” diameters to 3/4” lengths over 4”

- ±1/32” diameters over 3/4” to 4” long ±1/32”

- Diameters over 3/4” in lengths over 4” ±1/16”

Diameter of Head

No machining or trimming has been done to the heads of these solid Monel rivets. Because of this, the circumference may be irregular, or the edges may be rounded or flat.The diameter of the rivet head shall be within -8° and +4° of the nominal head diameter.

Height of Head

+8°/-4° of the nominal or basic head height, but in no case less than ±0.005”.Out-of-Roundness of Head & Eccentricity of Head in Relation to Shank (In Inches)

| Nominal head diameter | Total dial indicator reading resulting from eccentricity and out-of-roundness not to exceed |

| Up to 1/4” | 0.015 |

| Over 1/4” to 3/8” | 0.020 |