Solid Brass Rivets

Brass rivets are a simple, yet reliable, fastener option. They are comprised of a solid shaft with a sturdy head at one end. During installation, the headless end of a solid brass rivet is deformed (either with a hammer or with a special rivet tool) to hold the rivet in place.

Brass solid rivets are among the most widely used permanent fasteners. They can be found in everything from blue jeans to architecture to marine equipment. Advantages of brass rivets include:

Brass solid rivets are among the most widely used permanent fasteners. They can be found in everything from blue jeans to architecture to marine equipment. Advantages of brass rivets include:

- High strength

- Natural corrosion resistance

- High thermal conductivity

- High electrical conductivity

- Decorative appearance

Round Head

|

Flat Head

|

Countersunk Head

|

Truss Head

|

Pan Head

|

Universal Head

|

Your #1 Brass Rivets Suppliers

Jay-Cee Sales & Rivet carries a huge, in-stock inventory of solid brass rivets, with a variety of diameters, lengths, and head styles to choose from. Our selection includes

- Round head solid brass rivets

- Flat head solid brass rivets

- Countersunk head solid brass rivets

- Truss head solid brass rivets (a.k.a. wagon box rivets)

- Pan head solid brass rivets

- Universal head solid brass rivets

Available body diameters range from 1/16” to 3/8”. Standard lengths range from 1/8” to 3-3/4”. Most of brass rivets are manufactured from CDA260 (ASTM B-134) brass. See individual product listings for additional information and specifications.

View our inventory below to find solid brass rivets for your application, or use the filters at left to refine your search. With over 150 options to choose from, you’re sure to find the brass rivets you need.

We are your #1 brass rivets suppliers! Order today, request a quote, or contact Jay-Cee Sales & Rivet for more info.

Why Use Brass Solid Rivets?

- Fast assembly: When using mechanical rivet installers with automatic feed, brass rivets can be installed as fast as 3 per second.

- Strong joints: The solid brass material, sturdy head, and swollen/deformed shank end create a reliable joint between two workpieces, with very high shear strength.

- Permanent: Once installed, brass rivets cannot be removed without tools and without destroying the fastener.

- Inexpensive: In general, solid brass rivets are far less expensive than threaded fasteners.

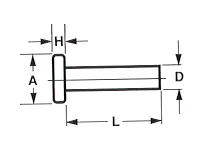

Standard Tolerances for Brass Solid Rivets

Diameter of Shank

| Nominal Diameter | Minus | Plus |

| 0.052-.094 | 0.001 | 0.003 |

| 0.095-0.156 | 0.001 | 0.004 |

| 0.157-0.219 | 0.002 | 0.005 |

| 0.220-0.375 | 0.003 | 0.006 |

| 0.376-0.625 | 0.004 | 0.008 |

| 0.626-0.875 | 0.006 | 0.012 |

| 0.876-1.000 | 0.007 | 0.015 |

Length of Shank

- Diameters of 3/4” up to 4” long, inclusive

- ±1/64” diameters to 3/4” lengths over 4”

- ±1/32” diameters over 3/4” to 4” long ±1/32”

- Diameters over 3/4” in lengths over 4” ±1/16”

Diameter of Head

The heads of our solid brass rivets are not machined or trimmed. Therefore, the circumference may be irregular, and edges may be rounded or flat.The diameter of the rivet head shall be within -8° and +4° of the nominal head diameter.

Height of Head

+8°/-4° of the nominal or basic head height, but in no case less than ±0.005”.Out-of-Roundness of Head & Eccentricity of Head in Relation to Shank (In Inches)

| Nominal head diameter | Total dial indicator reading resulting from eccentricity and out-of-roundness not to exceed |

| Up to 1/4” | 0.015 |

| Over 1/4” to 3/8” | 0.020 |

Contact Us for Solid Brass Rivets & More

If you’re looking for brass rivets or other fastener solutions, look no further than Jay-Cee Sales & Rivet. We also offer solid rivets in aluminum, copper, Monel, steel, and stainless steel, along with large diameter solid rivets. Order today, request a quote, or contact us for the brass rivets you need.